MRA’s Smart Stockyard Management System Improves Mine to Port Efficiency

Smart stockyard management for materials handling applications

As mining product stockpiles across the world continue to rise steadily, companies are faced with the challenge of balancing the benefits provided by maintaining stockpiles – such as guarding against supply fluctuations while also managing costs associated with stockyard management.

The stockyard is a critical component in the bulk materials handling supply chain at both the mine site and port. The port-based stockyard can represent a billion-dollar investment in real estate, large-scale machinery and automation.

Given such a significant investment in infrastructure, the more efficiently materials can be processed through the stockyard, the faster the payback and higher the operating profits. Smart automation can help organisations optimise material flow into the stockyard and onto the train

or vessel.

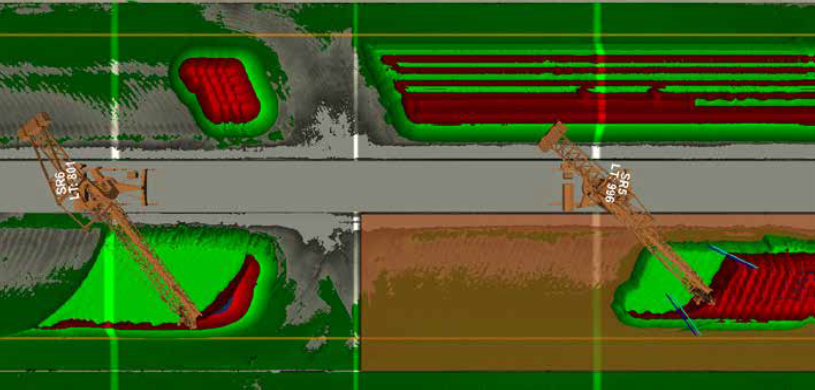

MRA is an engineering firm based in Newcastle, New South Wales, that specialises in mine and port machine automation. MRA has developed the Smart Stockyard Management System that combines smart engineering and leverages the latest control and automation technologies from Rockwell Automation. The system can optimally manage and automate the inbound receipt and outbound delivery of mined material including, coal, iron ore and bauxite.

Find more information about the deployment of MRA's Smart Stockyard Management System here.