High-Intensity Dry Vibrating Magnet Filter Removes Fine Iron-Bearing Contaminants From Lithium and Other Hard-To-Flow Powders

Eriez® high-intensity Dry Vibrating Magnet Filters (DVMFs) are specifically designed to remove magnetically susceptible contaminants from very fine powders such as lithium, silica flour, glass powder, talc, clays and various other difficult to flow industrial minerals and chemical products.

The DVMF is perfect for both lithium producers and other critical industries. Producers of lithium pulverize it into a very fine powder before it is it sold to downstream processors for further refinement and ultimately as battery-grade material. DVMF units are typically positioned prior to and after milling. As an additional safety measure, downstream processors have come to rely on DVMF’s within their own processes at the materials receival area.

DVMF’s dramatically reduce contamination in lithium such as iron, steel, chromites, stainless steel etc. by utilizing a high-intensity electromagnet and revolutionary flux converging matrix. The DVMF is fed vertically via gravity flow. As the feed material filters through the matrix and exits out the bottom, the matrix captures and holds the magnetic impurities as the nonmagnetic product passes through.

Capturing and retaining fine contaminants requires a high-intensity, high-gradient magnetic field amplified by the matrix. The matrix located within the cannister becomes the collection site for the magnetic contaminants as the feed filters through. The canister is attached to dual high-frequency, low-amplitude vibratory drives. These drives generate a strong vibratory action to the canister assembly which enhances the fluidity of very fine difficult to flow powders, resulting in a smooth and even transition of product through the matrix. This has proven to be the most effective filtration method available.

Eriez DVMFs are available in two strengths: 2,000 and 5,000 gauss (0.2 and 0.5 Tesla). In some cases, the 5,000 gauss units reduce contamination down to parts per billion.

Eriez state-of-the-art DVMFs are fully automated and feature a simplified cooling system. Other highlights include programmable controllers and the ability to handle 100mm to 300mm diameter sizes. Standard background magnetic field capacities are based on fine powder flow range up to 7.03 kgf per square centimetre of cross-sectional area of matrix. A 150mm diameter can treat up to 1,270 kg per hour of material weighing 6,410 kg/m3.

Design Characteristics

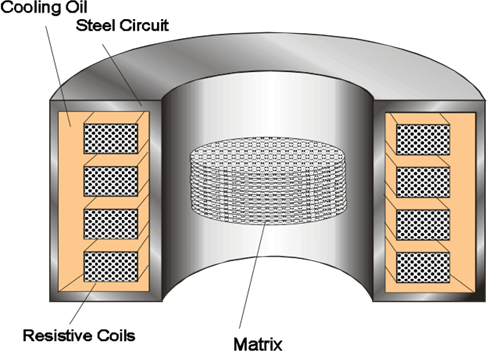

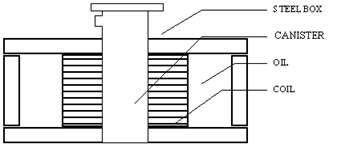

The magnetic filters consist of a solenoid electromagnetic coil enclosed in a steel housing. Schematics 1 and 2 illustrate the 2,000 gauss and 5,000 gauss Eriez DVMFs. The coil generates a uniform magnetic field throughout the bore of the coil, which represent background magnetic field. A stack of expanded metal discs are packed in the bore and induced by the magnetic field. These expanded metal discs, termed the matrix, provide the vehicle for separation. The matrix amplifies the background magnetic field, produces local regions of extremely high gradient and provides the collection sites for magnetic particle capture.

The magnetic force acting to capture a magnetic particle is proportional to the product of the magnetic field intensity and the magnetic field gradient. In equation form:

Where Fm is the magnetic force acting on a particle, H is the background magnetic field, and dH/dx is the magnetic field gradient (convergence of flux) generated on the matrix. Utilizing a relatively high background magnetic field coupled with an extremely high magnetic field gradient results in a high-intensity high-gradient separator. See Schematic 3.

A matrix type separator substantially improves the capture of fine particles. In a matrix, the material must filter through several layers of highly induced magnetic grids, increasing the probability of capturing more contamination over conventional plate, grate, trap or drum type separators. Even with relatively large matrix spacing, the material is subject to this filtering effect, resulting in the capture of magnetic material.

The dry filters are rated by the magnetic field strength generated in the bore of the solenoid coil with the matrix removed. The background magnetic field, often termed the open bore field, represents the driving force that produces the amplified high magnetic gradient throughout the matrix. Depending on the matrix configuration, it is typically the case that a 5,000 gauss background field will result in an excess of 10,000 gauss in localized regions of the matrix.

The electromagnet is a solenoid coil completely sealed in a steel housing. Standard model filters generate background magnetic field strengths of either 2,000 or 5,000 gauss. The solenoid coils are wound from copper to dissipate heat and operate at relatively cool temperatures. The 2,000 gauss models operate with static oil cooling. The 5,000 gauss models are oiled-cooled and utilize a heat exchanger where it is cooled with a 38 litres per minute water flow.

Operating Characteristics

The background magnetic field is typically determined through an identification of the magnetic material or by quantitative testing. Eriez’ experience has established some general guidelines for selection of the proper magnetic field selection.

For example, the 2,000 Gauss unit is used to handle fine to relatively coarse (50 micron and larger) ferromagnetic iron of abrasion or scale contaminants.

The 5,000 Gauss unit is perfect for very fine (minus 50 micron to sub-micron) ferromagnetic iron of abrasion, scale or paramagnetic contaminants such as ilmenite or chromite. It is specified when a high-purity product is required and where product specifications call for parts per million (ppm) contaminants levels. Again the DVMF achieves parts per billion removed performance.

Duty cycles (operating time of the magnet between cleaning cycles) are typically determined by identifying the amount of magnetic material contained in the feed product. Materials containing up to two percent contaminant may require very frequent cleaning. In these applications, the duty cycle may approximate 10 to 20 minutes. In this scenario, an automated feeding valve and reject gate are recommended. Treating relatively pure materials which may have only average ppm levels of contamination allow relatively long duty cycles, sometimes over an hour.

Eriez is recognized as world authority in separation technologies. For more information, please call us on 613 8401 7400, email [email protected] or visit our website eriez.com.au.

Schematic 1: 2000 and 5000 gauss Dry Vibrating Magnetic Filter

Schematic 2: The DVMF consists of a thick steel box with a canister in the bore. Aluminum or copper coils are positioned around the canister. Direct current power energizes the coil and allows the matrix to collect magnetic particles.